How Dairy Farmers Are Reducing Methane and Greenhouse Gas Emissions

It’s quite possible that the BMW speeding by you on California’s Interstate 5 is running on cow power. Same for that heavy duty truck over in the slow lane.

The Port of Los Angeles? Also keeping the cargo moving thanks to moo-inspired hydrogen.

The dairy industry has long made its mark fueling humans with nutrient-dense milk and other dairy foods. Many of the nation’s nearly 29,000 dairy farm families have also evolved their dairies in a decades-long commitment to planetary health, and they, along with scientists and technology experts, continue to unlock a cow’s potential to combat global warming.

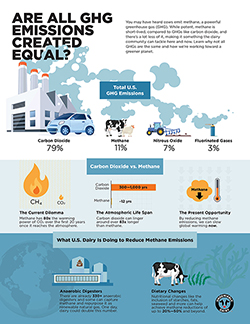

Across the United States and the rest of the world, there is a renewed emphasis on reducing methane, a greenhouse gas that contributes to our current climate crisis. Nick Gardner, senior vice president of sustainability and multilateral affairs for the U.S. Dairy Export Council, said while much of the global focus over the years had been on carbon dioxide, cutting methane emissions gained significant attention last November following the announcement of the Global Methane Pledge at the United Nations global climate summit, commonly referred to as COP26.

The U.S. and European Union have been joined in the pledge by more than 100 countries that together are responsible for nearly 50% of global human-caused methane emissions. These countries have committed to collectively reduce methane emissions by at least 30% below 2020 levels by 2030, seeking to reduce global warming by 0.2 degrees Celsius by 2050.

Although fossil fuels and waste disposal comprise major sources of methane emissions, agriculture, and specifically livestock operations such as dairy, are in the crosshairs of this global methane-reduction effort. But technologies and resources have created possibilities that are causing people to see dairies not as an environmental threat but as an environmental solution.

A truck at a Shell fueling station in Carson, California, where heavy-duty trucking customers can fill up on the compressed renewable natural gas.

One of those is the production of renewable natural gas (RNG), which is of growing interest to American consumers, including many who want every fill-up to come with a story of sustainability. Producing milk comes with the potential to produce methane-rich biogas, which occurs when cow manure decomposes. Recovering the methane creates a source of renewable energy for electricity, heating or clean, carbon-negative transportation fuel.

What Is Methane? How Do Cows Emit Methane?

Methane is emitted at dairy farms one of two ways. Enteric methane comes directly from the mouths of dairy animals. It is produced in the cow’s rumen through the digestion process. Think of it as a hearty burp after a good meal.

The second source is the manure that comes out of the back end of a cow. (No, it’s not cow farts.) Methane from manure can be generated under certain conditions, such as during storage before it can be further used for fertilizing crops. On many farms, the manure is stored in water and gas-tight vessels or lagoons that promote the production, capture and beneficial reuse of methane.

The world’s leading scientists tell us methane doesn’t have a very long lifespan compared to other greenhouse gases (GHG). It is a short-lived GHG that degrades in the atmosphere after about 10 years, a blink compared with carbon dioxide, which can linger for thousands of years.

But methane still is a potent cause of global warming, and dairy farmers want to continue to mitigate its impact while making use of a biogas with unlimited, energy-rich potential.

This is how anaerobic digesters for capturing methane come into play. These systems use bacteria to maximize manure breakdown in sealed vessels designed to keep out oxygen and capture the methane-rich biogas generated, and they are growing in use on dairy and other livestock operations.

Dairy-Sourced Renewable Natural Gas

The California dairy industry is ground zero for methane digesters and represents about half of the systems in place around the U.S., with 206 projects planned to capture methane on 217 farms.

Dairy farmers in California have found success joining “clusters,” which are groups of farms with digesters that share a centralized gas cleanup facility. There, the captured biogas is upgraded and then injected into the natural gas pipeline where it can be used as transportation fuel.

California is home to 16 clusters of digesters in various stages of development. Dairy farmer Joey Airoso is a partner of the original cluster launched in 2018 that is working with Calgren Dairy Fuels, Maas Energy Works, and 14 other dairy farm families.

California dairy farmer Joey Airoso dreams of a day when there is a better understanding of just how beneficial he and other farmers are to the earth.

Twenty-two-plus miles of underground pipeline link 12 dairies that pump biogas and two other farms that haul biomethane via tube trailers to the conditioning facility. This dairy-sourced renewable compressed natural gas (R-CNG) is used by heavy duty trucks, replacing 3 million gallons of fossil-fuel diesel with near-zero emissions.

“It’s been a really good relationship,” Airoso said. “There’s always plenty to do on a dairy farm and we don’t need things added that we’re not familiar with. I was really worried about the management of it, but Calgren manages everything on site, which is pretty minimal.

“It’s nice that you don’t have added traffic at the farm because we’re food-producing entities and we need to maintain on-farm security and you can’t have a lot of people in and out of here,” he added.

Shell plc is one of the major players involved with RNG and has turned to dairy as a solution. Shell, which has energy operations in more than 70 countries and all 50 states, announced its target to become a net-zero emissions energy business by 2050.

It has committed to providing lower-carbon transportation options and last September announced the startup of an RNG facility in Oregon that combines excess agricultural residue with dairy manure to produce gas. The company also announced plans for RNG facilities to be co-located with dairies in Idaho and Kansas, both of which are under construction.

“There are many reasons the dairy industry is an appealing party to work with,” said Karel Kapoun, general manager of RNG for Shell. “In particular, we have been impressed with the dairy industry’s innovation, forward-thinking mindset, and desire to ‘do more’ to aid in progressing sustainability.”

Shell also began incorporating dairy cattle into its Animal Welfare Report in 2020 and reached out to the National Dairy FARM Animal Care program to leverage its expertise and work collaboratively.

“Working with dairies and farmers is another example of how Shell continues to work across sectors as a party for change, furthering innovation and progress to a net-zero emissions world,” Kapoun said. “While our industries may seem different, we can come together to create solutions to energy challenges and enable greater sustainability. Shell is proud to collaborate with the dairy industry to propel energy progress.”

Scaling Methane Digesters

Patrick Serfass, executive director of the American Biogas Council, said dairies are a desired partner for the more than 260 companies and 3,000 professionals who comprise his organization. The council’s goal is to maximize the production and use of biogas from organic waste.

Serfass said while wastewater facilities remain the largest biogas sector, “agriculture has always been an important piece of the puzzle because of how strong the sustainability story is and how important it is to agriculture.” He describes a “closed loop system” on dairies with digesters.

“You have cows eating feed that’s grown in the fields, they then produce milk and manure,” he said. “That milk needs to be delivered every day and those trucks need to be fueled, so you can fuel those trucks with biogas that comes from manure. The milk processing facilities produce wastewater and that can be sent back to the farm to produce more biogas and then use the digestive (byproduct) material from the biogas system to increase your crop yield. In many cases we have found that the digestive material from the biogas system improves crop yields 10% to 30%. Those numbers are big enough to appeal to any farmer.”

This anaerobic digester on a Vermont dairy collects food waste that would have ended up in landfills and turns it into renewable natural gas for the community.

One other benefit of digesters is that farmers can work with their communities to accept food waste. Such is the case with Vermont dairy farmer Chase Goodrich, who never imagined his farm would become a destination for food scraps. However, that all changed when the state passed a law in 2020 banning items such as peels, seeds, pits, bones, tea bags, coffee grounds, eggshells and grease from landfills to reduce GHG emissions.

“When that went into effect, it raised the question, ‘What do we do with it now?’” Goodrich said.

A fair bit of it heads to his farm, which he manages with his sister Danielle. Long before the law went into effect, they planned to install an anaerobic digester to manage the manure from their 900 cows and to develop an additional revenue stream.

The food scraps are a bonus and are entered into the 1.32-million-gallon anaerobic digester, created in partnership with Vanguard Renewables, Vermont Gas Systems and Middlebury College. Middlebury purchases most of the RNG—helping the school reach its goal of transitioning to 100% renewable energy—with the remainder used by Vermont Gas Systems’ customers. Vanguard developed, owns and operates the digester and set up an office at the dairy with two staff members overseeing its operation, allowing Chase and his sister to keep their focus on the cows.

“It’s a huge undertaking and running this digester is a full-time job,” Chase said. “They allow us to do this project without having to have our hands in it every day, and we can go take care of the rest of the farm.”

Adding a digester to a farm is not an easy task with systems ranging into the millions of dollars, but there are methane mitigation solutions on dairies beyond digesters. Minnesota farmer Suzanne Vold has a compost drum on her dairy, likening it to “a big Pringles can laying on its side.”

Her Daritech “BeddingMaster” relies on composting “101” to effectively manage the manure from Vold’s 420 milking cows. The cows’ manure is collected by a system of robotic “scrapers” and placed into the composter, along with paper waste from the farm. An auger slowly rotates the manure and waste to keep the oxygen moving. It eventually reaches temperatures of about 150 degrees, eliminating the bacteria in about 24 hours.

What results is a fluffy, odorless, soil-like product that makes for clean, comfortable bedding for Vold’s cows. It also is sought after by local growers and gardeners.

Large composters like this one on a Minnesota dairy are also effective at mitigating methane.

“We’ve been doing things for generations on our farm that have been good for the planet; we just never called it ‘sustainability,’” said Vold, whose dairy has been in her family for 125 years. “We live where we work, and it’s in our best interests to protect our natural resources. We also want to pass our farm on to the next generation and to do that, we can’t run it into the ground.”

Research for Cow of the Future

Juan Tricarico, Ph.D., is an expert in the cow’s digestive and rumen system and understands very well the role nutrition can play in methane reduction. He remembers “moon shot” discussions as part of the dairy industry’s “Cow of the Future” program years ago.

“We had an exercise with the Cow of the Future research consortium and within that work we did what we called ‘moon shots,’ and one of them focused on imagining cows that produce no enteric methane,” said Tricarico, vice president of sustainability research for the farmer-founded Dairy Management Inc., an organization that grows sales and trust on behalf of U.S. dairy farmers and importers.

Tricarico is encouraged by the amount of sustainability-based research commitments being made to dairy. One of the latest is the Greener Cattle Initiative, a global five-year initiative to support research and ultimately provide dairy and beef producers with effective, scalable and commercially feasible solutions to mitigate enteric emissions.

Through this initiative, the Foundation for Food & Agriculture Research, (FFAR), Innovation Center for U.S. Dairy and several industry partners formed a public-private partnership to develop and evaluate feed ingredients, technologies to monitor emissions, breeding programs that produce low-methane-emitting cattle, and socioeconomic analysis of practices.

“This is the vision of the future,” Tricarico said. “Its objective is to discover new knowledge and will allow us to be very ambitious looking forward.

“A few years ago, I might have said it’s impossible for a cow to not produce any methane. Today, I say let’s look at microbial ecology and put some funding into research that just may give us opportunities that we have never dreamed of.”

Changes to feed can also help with the methane produced from cows.

A lot of progress has been made with feed additives to help minimize the effect of enteric (“cow burp”) emissions, which account for about a third of a dairy’s GHG footprint. Incorporating an additive improves digestibility, and Frank Mitloehner, Ph.D., a noted University of California, Davis professor and air quality specialist, says some additives could potentially reach 30% methane reduction in the coming years.

There has been a lot of buzz surrounding an additive called 3-nitrooxypropanol (3-NOP) and its ability to reduce emissions. The European Food Safety Agency declared 3-NOP, branded as Bovaer, safe for cows, consumers and the environment.

Alexander Hristov, Ph.D., a distinguished professor of dairy nutrition in the department of animal science at Penn State University, conducted in-depth research on 3-NOP. His team found it could cut methane emissions by as much as 30%, which helped the product earn approval in the European Union and some South American countries.

In the U.S., the Food and Drug Administration classifies 3-NOP as a drug, which requires a different – and in some aspects, more stringent – review process, before this additive can be approved for use by U.S. dairy farmers.

“In terms of feed additives this is the only one that is proven, including in long-term studies, and practical,” Hristov said. “Now, there are lots of other companies out there and we have worked with some of them that claim a mitigation effect, but I can tell you that none of these have a consistent, proven effect in independent studies.

Beyond 3-NOP, there are other potential options being explored globally. Scientists are evaluating the effectiveness of feed additives including bromoform-containing red seaweed, plant extracts and essential oils from common plants such as oregano, garlic, cinnamon and others. Red seaweed (or asparagopsis taxiformis), for instance, is currently being researched actively in various institutes and universities around the world. A blend of plant extracts, including wild carrot and coriander seed oil, also shows promise in reducing enteric methane while also potentially increasing feed efficiency.

Dairy’s Dedication to Sustainability

The U.S. dairy industry showed how committed it is to sustainability with the announcement of the 2050 Environmental Stewardship Goals, which address areas where dairy collectively can have the greatest impact, specifically:

- Achieve GHG neutrality

- Optimize water use while maximizing recycling

- Improve water quality by optimizing utilization of manure and nutrients.

Following this announcement, the U.S. Dairy Net Zero Initiative (NZI) was launched in 2020 led by six national dairy organizations to break down barriers to help all farms of varying sizes, designs and geographies reduce their environmental impact. The practices and technologies needed to reach the stewardship goals largely exist, but require further development, significant operational changes and advanced technical assistance. NZI supports U.S. dairy farms to implement new technologies, adopt economically viable practices and create new markets and products, presenting new revenue opportunities for the environmental assets they generate.

Much of this research and action is made possible with support from major companies. One of the first NZI partners is Nestlé USA, which last year made a $10 million commitment to test technologies focused on feed production, enteric methane reduction, energy efficiency and manure management on one pilot farm.

The first farm identified to participate, California’s Trinkler Dairy Farm, has been supplying milk to Nestlé’s CARNATION® brand since 2014. The farm is seeking to reduce its GHG emissions 30% by 2023, thanks to the installation of a methane digester made possible by Nestlé.

Dan Peerless, global sustainable sourcing lead for dairy, meat, poultry and eggs at Nestlé, said working with farmers is critical to the company’s goal of achieving net zero emissions by 2050. He said most of Nestlé’s emissions result from its supply chain, with dairy accounting for about 16% of its overall U.S. carbon footprint. While Nestlé is a global business, U.S. dairy farms represent the most significant sourcing region of milk for the company.

To make partnerships with farms succeed, Peerless said it’s important to have conversations with farmers to identify what works best for them.

“We’re really agnostic as to what those projects could look like,” Peerless said. “We ask the suppliers and their farmers to make proposals to us. We do not want to pretend to know what is best at each farm or each region or that we know as much as the farmers know. We trust the industry to discover opportunities that don’t place undue burden on the farmers.

“Being able to be part of and support and hopefully accelerate U.S. dairy’s movement toward net zero is completely aligned with our own strategies.”

Karen Scanlon, executive vice president of environmental stewardship of the Innovation Center for U.S. Dairy, says Nestlé is just one example of how major companies are coming to the table to discover solutions through science-based proof. Starbucks also announced a $10 million, multi-year commitment to support NZI, and Syngenta, The Nature Conservancy and FFAR, announced a collaboration with dairy farmers to reduce GHG emissions, improve water quality and strengthen farm resilience.

“I think that points to the potential that others see within dairy,” Scanlon said. “Attracting partners who are recognized as leaders and experts signals the potential that others see within dairy,” Scanlon said. “Basing our actions and measurement in science further adds to the rigor, integrity and credibility of our work and supports our ability to demonstrate to consumers that dairy is an environmental solution.”

This science-based approach is critical to representing U.S. dairy internationally as well.

“The reality is the global marketplace is going to demand a disciplined approach with the ability to demonstrate progress toward reduction of all environmental impacts,” USDEC’s Gardner said. “I think methane is the one they’re appropriately focused on now as it has the greatest potential to reduce heating of the planet in the short term and it will be the one that gains the most attention as we look to goals tied to a 2030 timeframe.”

Airoso is well aware of the discussions on methane that occur in California and beyond. He dreams of a day when there is a better understanding of just how beneficial he and other farmers are to the earth, starting with the star of the farm.

“My biggest gripe is the cow is not the world’s biggest problem,” Airoso said. “If the cow is the main problem on this planet, then you’re kidding yourself. You have a cow that consumes a lot of byproducts, which used to end up burned or in a landfill. She uses that feed to produce nutritious milk as well as manure, which we’re now using to produce energy. This doesn’t include the number of jobs that have been created on our farm because of our partnership and others across the country.

“You put this all together and this is a very big deal.”